Laboratory techniques related to the oligonucleotide (oligo) synthesis process are the backbone of genetic research and innovation. However, the intricate nature of these processes leaves room for human error, which can jeopardize the accuracy and reliability of results. In this blog, we explore the role of human error in the oligo synthesis process and how automation can be a powerful solution to minimize these errors.

For a limited time, take advantage of our exclusive offer to enhance your oligo synthesis workflow using our recommended tools. Skip to the bottom of the page to learn about Biolytic’s accessories.

The Delicate Balance of the Oligo Synthesis Process

Oligo synthesis involves the careful assembly of nucleotides to create customized DNA or RNA sequences. The success of experiments and research heavily relies on precise execution, as even the slightest error can lead to misleading data or failed outcomes.

Common Human Errors in the Oligo Synthesis Process

- Measurement Inaccuracies: Miscalculating reagent quantities or volumes can alter the final sequence, potentially rendering experiments invalid.

- Procedural Mistakes: Complex multi-step processes demand strict adherence to protocols. Skipping steps, mixing them up, or ignoring time-sensitive procedures can disrupt the intended outcome.

- Contamination Concerns: Accidental cross-contamination between samples can introduce foreign genetic material, skewing experimental results and analysis.

- Documentation Oversights: Poor record-keeping makes it difficult to trace the source of errors, hindering troubleshooting and resolution.

The Power of Automation in Error Mitigation

Automation in the oligo synthesis process offers a promising solution to combat human errors and improve the overall reliability of laboratory results. By leveraging advanced robotics and software, several benefits arise:

- Precision and Consistency: Automated systems follow protocols consistently, reducing variations that can arise from human execution. This ensures that each synthesis is performed with a high degree of accuracy.

- Accurate Measurements: Automated liquid handling systems precisely measure and mix reagents, minimizing the risk of measurement errors and improving the quality of the synthesized oligos.

- Procedural Adherence: Automated platforms strictly follow programmed protocols, eliminating the possibility of human-induced procedural mistakes.

- Contamination Control: Robotic systems minimize the risk of cross-contamination by ensuring that samples are handled in a controlled environment.

- Documentation and Traceability: Automation generates detailed electronic records of each step, simplifying troubleshooting and aiding in the identification of errors.

- Time and Efficiency: Automation accelerates processes, enabling researchers to conduct experiments more efficiently and potentially increasing the volume of research output.

Biolytic’s Tools to Increase Oligo Synthesis Success

With over 30 years in the oligonucleotide synthesis business, we have experienced the common pain points and procedures where human error can occur during the oligo synthesis process. With our industry experts, we have developed low-cost, and low footpr威而鋼 int tools to introduce automation to these pre and post synthesis processes to ensure consistent and high-quality laboratory results.

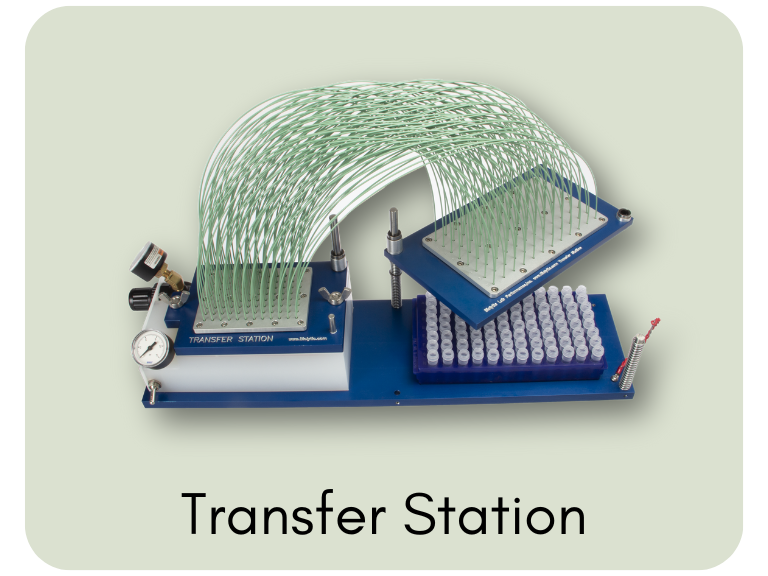

Transfer Station

Transferring liquid from a 96 well plate to 96 individual vials currently involves either an expensive robotic system or the manual method of using a pipette (multi-channel with adjustable centers or single channel). In either case it is time consuming and prone to translation errors.

Our product was developed to solve both of these issues. A simple and low tech solution that uses positive pressure to move fluids (oligos, peptides or other samples in liquid) from a 96 well plate format to 96 screw cap vials quickly and easily without translation errors.

Features

- Utilizes gas pressure to transfer liquid easily between well plates and vials

- Eliminates transfer translation errors

- Prevents cross contamination

- Saves time over manually pipetting

- Easily cleaned between transfers to eliminate carryover

- Height adjustable platform with spring tensioner to accommodate different size well plates and vials

- Compact and sturdy design

- Custom modification to fit many popular screw cap vials

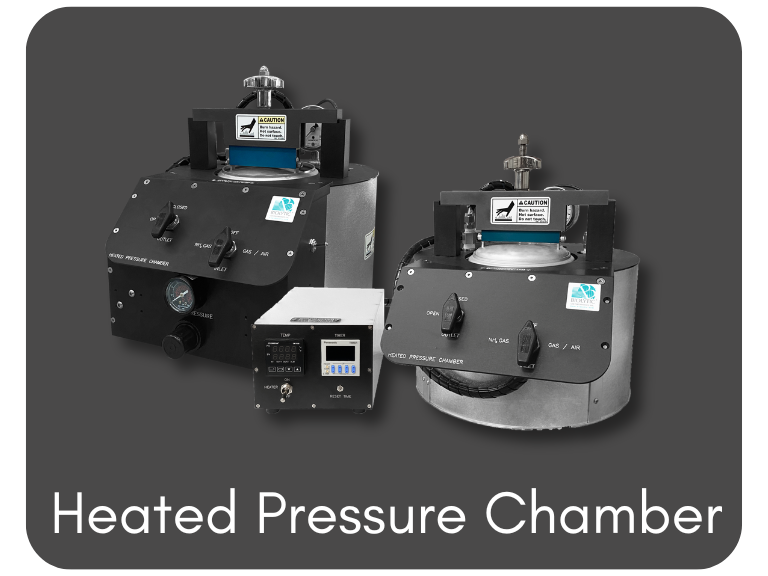

Heated Pressure Chamber

The Heated Pressure Chamber turns gas/vapor phase cleaving and deprotection into an efficient single-step operation. Synthesis Plates and Synthesis Columns in racks are placed directly in the reaction chamber. Upon gas deprotection, products such as oligonucleotides can be directly desalted, then eluted from the synthesis support with your buffer of choice, no transfer step needed.

Column Press

Fitting synthesis columns into a 96 well rack has traditionally involved pressing each column into each hole. In order to create a tight seal the column needs to be flush with the top of the rack. Performing this operation by hand can be long and arduous. In many cases people opt to forcefully pound the columns in with a hammer. Both methods are time consuming and in the case of using a hammer, it can cause serious damage to the synthesis rack and/or synthesis columns.

The Biolytic Column Press solves these issues with a simple economical product that allows for fast, easy fitment and removal of synthesis columns into a 96 well rack without damage to the rack or columns.

Features

- Easily insert and remove columns into a standard 96 well rack

- Damage free system extends the lifespan of racks and columns

- Reversible press tool allows columns to be pressed below the top of the rack

- Slide out bin collects any extracted columns

- Columns can be removed but kept in rack for position reference

- Glenpak and CTGen media friendly

- Storage area for standard or universal support columns

- Solid aluminum frame

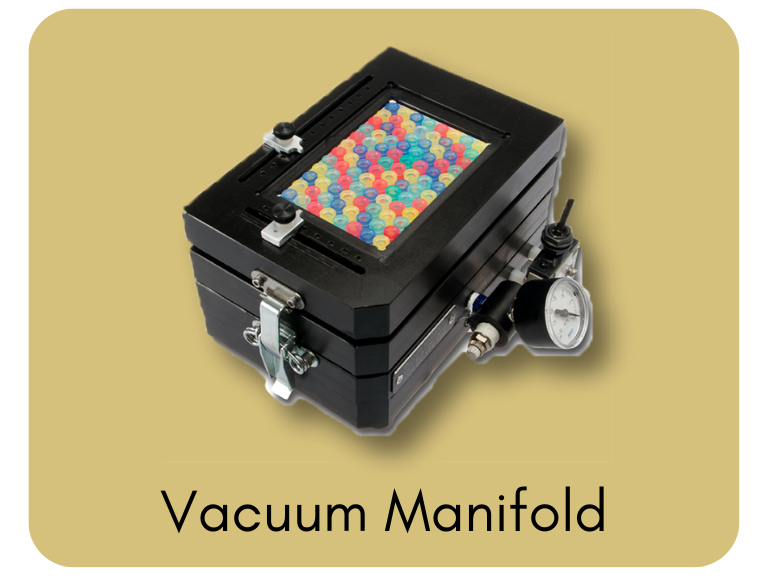

Vacuum Manifold

The Biolytic Vacuum Manifold allows for easy sample filtration and sample collection. Filtered samples can be deposited in a deep well plate or in a rack of tubes for storage and transport. It also features an easy latch system which securely clamps the assembly to ensure a steady vacuum. Sliding indicators on the column and row axes add extra control and aid organization. A vacuum trap and waste drain protect the vacuum pump from clogging and eliminate the hassle of emptying the manifold after each use. The small accessory minimizes it’s footprint in the laboratory, saving more space than a large centrifuge.

Common Uses:

- Sample filtration

- Sample collection

- Oligonucleotide, DNA, RNA cleavage

- and more

Conclusion

Laboratory techniques related to the oligo synthesis process demand precision and meticulous attention to detail. Human errors can compromise the integrity of experiments and research outcomes. Automation emerges as a powerful tool to address these challenges, enhancing accuracy, reproducibility, and efficiency in the laboratory. By embracing automation while maintaining a balance with human expertise, scientists can elevate the quality of their work and drive transformative advancements in genetic research.